Over Christmas vacation, I completed all the component mounting

on my MFOS Ultimate board.

Over the next several months I'll be building what is definitely

my most complex electronics project to date: the MFOS (Music From

Outer Space)

Sound Lab Ultimate,

Ultimate Expander and (if Santa brings one)

Sound Lab Mini-Synth Mark II, likely all in the same home-made

wooden case, side by side. The Ultimate and Expander are together a

3 oscillator monophonic true analog synthesizer with filters,

envelopment generator, ring modulator, sample and hold and more.

You patch between the different logical modules using banana

cables, so it's a bit of a self-contained modular synthesizer. The

Mark II is smaller, newer, and has a few fewer features, but a

sound of its own. You also patch that with banana cables, and can

integrate the two. This blog post is another in the series.

Previous posts include:

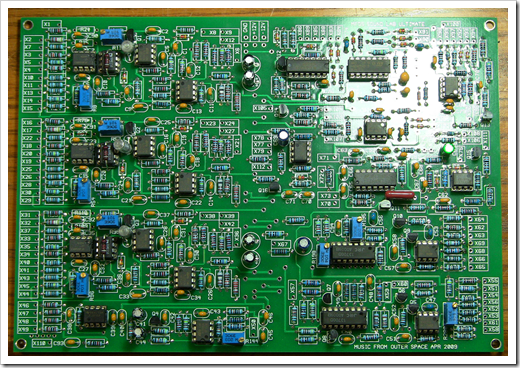

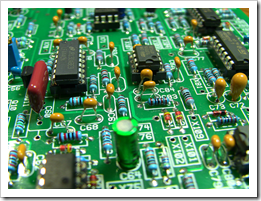

The board now has installed all the capacitors, resistors,

diodes, ICs, trimpots, and transistors specified in the parts

list.

Here's the overall shot of the board. For the most part, I tried

to use the best components I could reasonably get. One place where

I decided to spring for a little bit better was with capacitors 49

and 50 in the filter. I don't have a DMM sensitive enough to

measure pF capacitance, so I couldn't measure and match those.

There are circuits you can build which will let you measure

capacitance, but I'm not particularly interested in building one.

Instead, I sprung for 1% tolerance capacitors figuring that will

get them pretty darn close.

A thing of beauty!

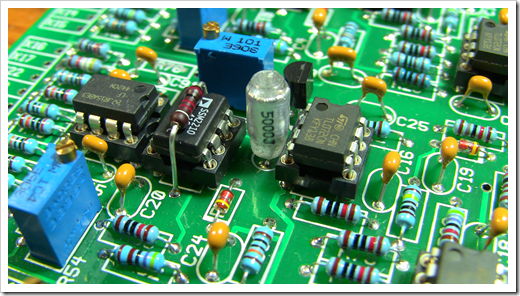

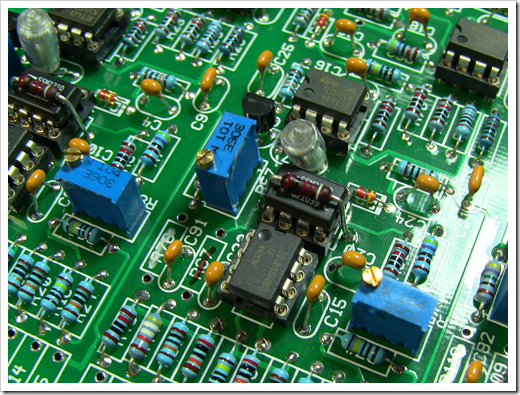

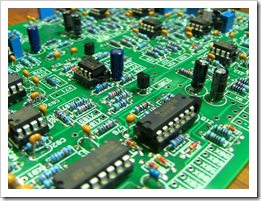

Here's a shot of one of the three oscillators. You can see the

2k ohm tempco (temperature compensating) resistor mounted over the

SSM2210. I don't have any appropriate thermal or potting epoxy

around, so it's just touching it right now. I'll bed it once I test

everything and I pick up the epoxy.

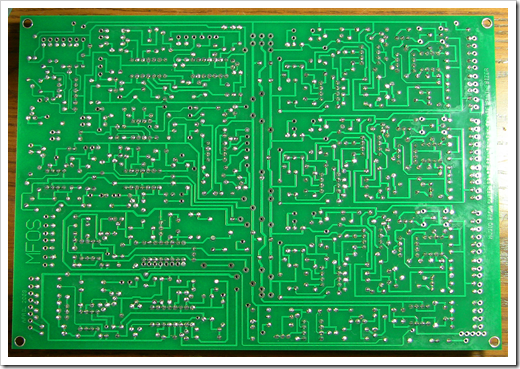

After I took these photos, I cleaned the bottom of the board

using Flux Off Rosin Flux remover by Chemtronics.

What a mess! It took the whole 10oz can to clean the board (at $17

a can!), and then it still (due to the "X" holes) redistributed

some of the sticky flux to the component side. Once I finished up

the can, I managed to get almost all of the flux off the top, and

all of it off the bottom. Still, what a mess. You have to spray

enough of the remover on to liquefy the flux and run it off the

board. Any dissolved flux which stays on the board simply spreads

out. That stickiness, if not removed, will attract dust and dirt,

making more of a mess of the board.

I'll give it this: the bottom *did* get clean. The burnt flux

from removing a couple mistakes (one transistor soldered backwards,

for example) was all washed off, as were the sticky hard globs of

resin.

Of course, this is before I solder on all the front panel wires,

so there will be flux from that too.

Flux can be corrosive over time, not to mention ugly, so it's a

good idea to clean it off. Other approaches to consider include

using 99% alcohol if you can get it. I just ordered order some of this, because it is likely the

same type of stuff for less than half the price of the Flux

Off.

Rosin flux is more benign than most, and actually cures hard to

entrap the contaminants. Don't get water washable flux unless you

intend to do a really thorough job cleaning the board. Typical

water washable flux is highly corrosive if only partially

cleaned.

I've also heard that the particular solder I used for this

project (60/40 from Radio Shack) tends to have quite a mess of

flux. Folks have recommended Kester 44 Rosin Core 63/37 as a better

replacement with both more stable soldering (less time in the

intermediate state) and cleaner flux. I have some on order for the

next few boards :)

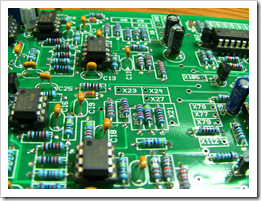

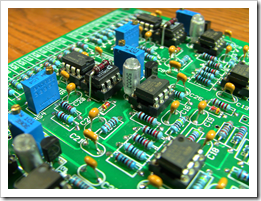

Here are a few more glam shots of the board

For the next step, I'll either work on testing and calibrating

the oscillators here (which will require building the 1V/Octave

test board), or I'll start wiring some of the panel. Whatever I end

up doing, I'll be sure to write about it here :)