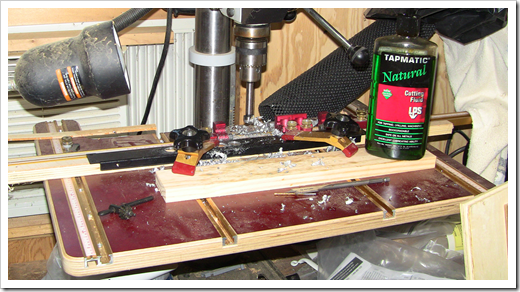

Today I spent a little time at the drill press in my shed, and

made a huge mess with aluminum and cutting fluid.

Before you read on, here are the other installments in this

series. You may wish to look them over first.

Spotting the Holes

As I mentioned, I went out and made a mess with chips and

cutting fluid. My goal was to quickly cut the rear openings for the

11 MIDI jacks and one power jack. The first step was to mark the

edge of each jack using a hobby knife. The lines will be the

centers of the drill points. I marked using the edges, but offset

the whole back first by 1/2 jack, making it much easier to get

accurate lines using the jack edges as a guide.

I wanted to use my Sherline mill for this, but it doesn't have

quite enough travel to cover the distance from one end to the other

in a single setup, and setting up a CNC operation just to drill

some holes seemed like a lot of planning for just a little work. I

probably will use it for the front panel, if I don't get one

commercially made.

I then drilled pilot holes, as I had expected to use spade bits

when drilling the aluminum. The pilot holes ended up being

unnecessary (and actually in the way) because spade bits are a

horrible choice. When I tried to use a spade bit on the first hole,

it wandered a bunch and instead of cutting through, simply pushed

the metal so it humped up a bit. What I really needed was a 5/8"

hole saw, but what I ended up using was a formerly very sharp 5/8"

forstner bit and a bunch of tapmatic cutting fluid.

Drilling the 5/8" Holes

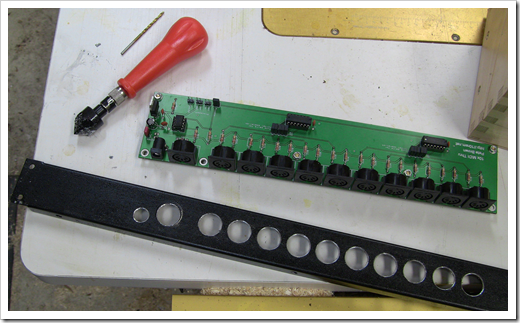

After completing the holes, I reamed them with a 3/4" hand-held

countersink. This removed the burrs and sharp edges. During the

process, I checked the back against the circuit board several

times. Despite that, things were still a little off, but will be

usable. I really wanted to have larger holes (more like 3/4") to

allow a tight fit for the fat plastic cable ends, but couldn't fit

that large a hole in the back.

After that was complete, I drilled a hole for the power jack,

and reamed it like the others.

Next, I had to cut some clearance holes for the standoffs. You

can see the half-circle holes here. You can also see how the

workpiece jumped out of the clamps at one point, and the bit

skittered across the bottom. It'll be covered by the board, but not

a great moment in metalworking history :)

Attaching the Board

The final step was to attach the standoffs to the circuit board,

spread epoxy on them, then hold it in place while the epoxy dries.

Another option would be to drill holes in the bottom of the case

and screw the standoffs in place, but the case top/bottom/sides are

made of steel, and frankly, epoxy is good enough for this.

The end result is decent. The 5/8" holes in the back don't

really leave any room for error, of which I had a fair bit. It

looks like I can get a good connection from each of them, but

they're not all quite centered.

Next Steps

Next I want to wire up a Netduino to this guy and try out some

of the more advanced ideas I had around routing and monitoring.

I'll post about that once I set it up.