I'm in the mood to build something. What I really want to build

is a big old analog synth, but I haven't worked my skills up to

that yet. This kit from Doepfer (which this beautiful and awesome but somewhat weak-sounding synth is based on) is

definitely an option to get me started, and is now sitting in my

"to do" pile here. (Incidentally, if I started with that kit and

wanted to make a fat synth, I'd want to use two of them plus add

some additional filters and effects. I'd also want to build it in a

way that would allow me to ditch those in the future and build

something even more complex in the same case/framework. It'll let

me do some nice woodworking at the same time.) (BTW, looking for

more DIY synth inspiration, check out this DIY digital - there are three

videos to watch: video 1, video 2, video 3)

I've been looking for a relatively easy electronics project, and

just happened to have a need with my synthesizers. I have several

synths in a rack, and depending on my mood, I only have a couple of

them powered up at any given time. However, because they're all

legacy MIDI rather than USB or OSC, I have them daisy chained

together. That means that if I want to use the last synth in the

chain (my Virus), all the other ones (M-VS1, Morpheus, JP-8080)

have to be powered on in order for the MIDI signal to make it

through. Not only is that a waste of electricity, it's also

personally annoying and adds to a very small (I can't really notice

it) amount of lag in the MIDI signal.

I previously built a MIDI interface for my Netduino, so I'm

familiar with the general design. However, I stumbled

across a circuit design for a MIDI through box that does

exactly what I want (I'd prefer a couple more midi outs, but I can

definitely live with 5 as I have 4 MIDI synths in the rack. If I

wanted more outs, I would add another inverter and discrete

components as necessary. I may even do that with the final version

of this board.) To that design, I added a power LED, and once I can

figure out how, I want to add a MIDI activity LED.

Parts List

Here are the parts used to make the board, along with links to

Mouser to purchase them.

Hardware

- Rack-mount case (I'll cover this below)

- Standoffs

- Screws

For the power supply, I wussed out and used and external brick

power supply. I wasn't sure that I could build a 1U power supply

and keep it electrically quiet, so as not to interfere with the

audio equipment in the same rack. I also didn't want to deal with

power supplies on this first real project. I'll deal with building

power supplies in a future project. Note that you can get a cheap

9v power supply from your local store. It only needs to handle

around 100mA +/-.

Prototype

I assumed the schematic was correct, but figured I'd prototype

it in any case. This would also allow me to experiment with the

power LED and activity LEDs.

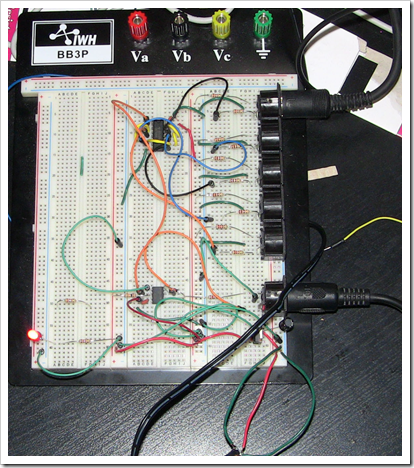

The image above shows the working MIDI Thru box circuit. I have

one input and five outputs. I tested all five outputs and they

worked on first go (amazing!). The power LED on the bottom seems to

be running a little hot, so I'll probably pop a larger resister in

there (currently it's a 220 ohm). I don't need a super bright power

LED in any case. I may even try a smaller LED. The hex inverter is

the one at the top. The opto-isolator is at the bottom, facing the

opposite direction. Slightly covered by the power cord is the 5v

regulator. There's no power switch in this prototype, but there

will be in the final version.

Rack Case

I want the final version of this to sit in my equipment rack.

Loose units banging around my desk annoy me, and get in the way of

all my projects. I tolerate them if there are no other choices (my

new DSI Tetr4, for example), but try and avoid loose modules

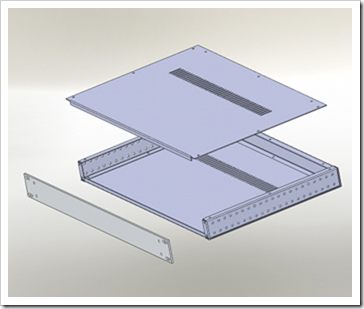

whenever possible. The 1U rack case I bought for this project is

from par-metal.com and is the 10-19082B (B is black

anodized front and painted black body). The case has aluminum front

and back, which means I can drill it with normal tools, and steel

otherwise. It's a 1U rack case 8" deep. From their description:

Front panel is 0.125" aluminum alloy (5052-H32) with brushed

finish in black or clear anodize. Other panels are 0.05" thick

steel, painted in black or gray. Rear panel is 0.06" thick aluminum

alloy (5052-H32) painted. Aluminum handles and hardware are

included.

All screw holes are installed with 6-32 steel press-nuts to

increase strength and reliability.

Standard vent holes are punched on top. Two rows of round holes

are punched on side panels for mounting channels or for use as vent

holes. Add suffix-x to indicate your choice of color or finish:

-B black anodize front & painted black

-G clear anodize front & painted gray

-E painted in beige

I have to say that I'm impressed with these guys. I

ordered the case late Tuesday night, paid by PayPal on Wednesday

afternoon, and received the case via UPS on Thursday

afternoon.

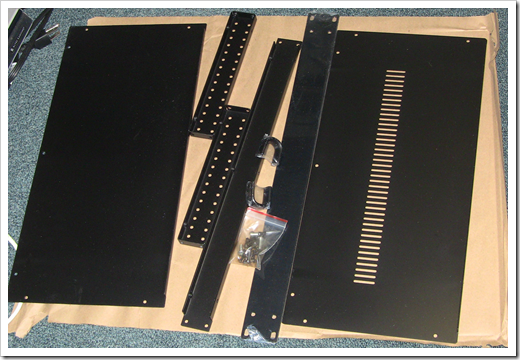

What arrived is a flat pack version of the case, complete with

hardware and those little handles. The front panel and the little

handles are all wrapped in plastic, so they're unlikely to get

scratched. The pieces were all separated by the packing paper in

any case.

For a more complex layout, like a synthesizer full of pots,

buttons, and encoders, I'd probably use something like Front Panel Express to do the panel work (or

build my own larger CNC machine. muah hahahaa!). However, in this

case, I simply have a few holes to drill in the rear of the unit

and one rectangular cutout for the power switch in the front, so no

worries. The steel pieces all have nuts attached so you don't have

to think about fitting your own, or dealing with shallow stripped

threaded holes. Perfect!

The aluminum front panel was nicely anodized (which will make it

slightly harder on my drills, but it's worth it) and the rest is

painted black. I'm not sure if the rear aluminum is anodized or

painted. The paint was nice and even, both inside and out, without

annoying drips, runs, or missed spots. There were no sharp edges.

Including shipping this case came to $57.50, which I think was an

excellent deal.

Here's a photo of it assembled, but with the plastic still on

the front panel. Note that if you want to use the little handles (I

haven't decided, but likely won't) you need to orient the sides so

the threaded end faces the back rather than the front.

Other than the front being aluminum instead of punched steel,

and this case being actually painted on the inside, there is little

to no quality difference between this case and the ones that hold

my other synthesizer rack modules. That's good. You'll want to use

aluminum fronts and backs rather than steel, if you intend to cut

the openings using normal tools.

Next Steps

Now that I have a working prototype on a breadboard, I've

started designing the circuit board in FreePCB. This is my first

time designing a board, so I fully expect to botch it somehow.

However, I'm doing this as much for the PCB experience as for the

actual utility of the project. The next blog post will go through

how I designed the board and, assuming I follow through with

getting it fabricated, I'll post a follow up with the results of

that as well (it can take several weeks to get a board depending on

how much you're willing to spend).