In addition to all the programming projects I have in my

backlog, plus things like migrating my website to a new provider

(and finishing migrating the old irritatedvowel hobby pages), I

have a number of fun maker-type projects I want to work on in the

near (and distant) future. In most cases, the projects would

require learning something very new - that's the appeal. If I can't

learn something new and interesting, I quickly lose interest in the

project.

Here are some things I'd really like to do, in no specific

order.

CNC Mill with Larger Work Envelope

I currently have a Sherline mill that has been modified with a

larger table, a

rotary table, and a

servo-based 4-axis CNC setup. I really like it, but the work

envelope is still small for what I'd like to work on. It also isn't

enclosed so it

throws chips everywhere. Enclosing would be a waste because the

14" of X travel requires a box way too big. I'd like to build

an enclosed system with a combination of the flexibility of a

router, but the stability and strength of a mill. It'd also need a

work envelope large enough to mill the front panel of a 19" rack

unit (in support of several other projects), but without taking up

a boatload of space. I already have some ideas for how to

accomplish this, including using eMachineShop to CNC mill a

few of the steel pieces I likely won't be able to do on my own.

I've already started purchasing some of the THK linear motion

components as I find them for reasonable prices on ebay. I already

use Rhino 3d and RhinoCAM Pro for modeling and CAM.

Inspiration includes the Roland MDX 540a and the enclosed MDX

40a, plus tons of other ones. Here's a shot of my "inspiration"

folder for the project. Early in the process of planning a project,

I often start collecting images and links that are similar to what

I'm thinking of doing. I collect those and store them in an folder

named Inspiration off the project root.

3D Printer

I've seen a number of 3d printer projects, and have to admit

that the resolution is getting

much better. Many folks like to build self-replicating

machines, which is awesome. However, I'd want to CNC mill the parts

to make it as accurate as possible to start with. Many of the home

made machines suffer from backlash in the screws, rigidity problems

and other issues which cause them to produce parts that have too

low a usable resolution. I'm no expert, but I can think of some

ideas from the CNC world that can help there. Of course, it's

unlikely that a hobby machine could get anywhere near the

resolution of a commercial device, which uses something almost like

an inkjet sprayer (or small laser) to either spray or harden

plastic.

Custom Gear Mill

Cutting gears can be done a number of ways on a mill. However, a

full 4 axis mill tends to be a bit of overkill for that. I'd rather

build a small but extremely rigid dedicated gear cutting machine.

If rigid enough, it could cut gears even in steel, something a more

general-purpose home-built mill is not really great for.

CO2 Laser Cutter

Not high on my list, but interesting anyway. There are sites now

dedicated to DIY CO2 laser cutters that can cut wood, plastic, and

even aluminum. Yeah, I'm interested.

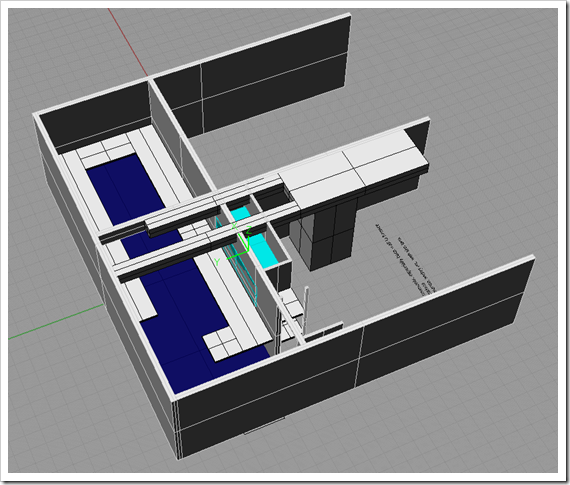

New Home Office

My current home office is in a corner of the basement with no

circulation. I want to move to the opposite side of this wall, and

move our upstairs tropical aquarium into this room, and upgrade it

to be larger. That side of the house has a window, more room, and

most importantly, doesn't share air with the heat-generating

washing machine and dryer. I have plans for this, it just requires

me to finish some home projects here to move the lumber and trim

out of that room.

The wall with the aquarium on it doesn't currently exist. Also,

this is the utility room, so there's some ductwork above that I

have to work around (and sound proof). The room would be a combined

projects workshop and office. The open space on the back wall is

required by code for access to the breaker box.

Quadcopter / Quadrotor

Yeah, flying robots are very cool. I'd like to build one (likely

on the larger CNC machine) with a camera, onboard navigation,

camera, and other goodies. Maybe guns and bombs too ;)

Here's the

latest progress from someone else doing essentially the same

thing, even powering it with the .NET Micro Framework. You have to

love the look on his daughter's face when she realized it wouldn't

yet fly :)

Steampunk .NET Micro Framework-Powered Robot

I have some great ideas for a .NETMF-powered steampunk styled

robot. I'd ideally like to have the larger CNC mill to complete

this. I'm thinking of one that looks is action figure-scale and

incorporates wheeled locomotion ideas from trains, but has a

proliferation of large custom-milled gears. Of course, I have an

inspiration folder for this too:

(Yes, say hello to the Doctor)

Minibots

I have a huge pile of really inexpensive small motor and wheel

sets. I'd like to either CNC mill or 3d print bodies for these

things and make an army of kid-friendly mini robots.

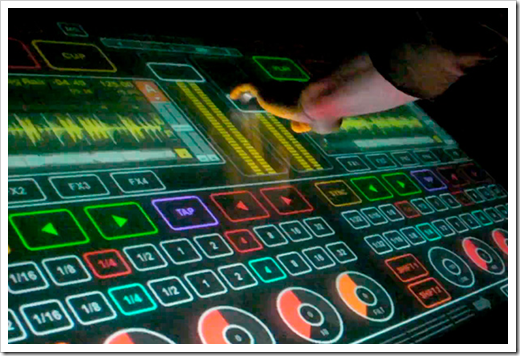

Surface-Like Touch Interface

There are lots of examples on the web of folks who have built their

own plexiglass and IR LED-based "big ass

tables". Also,

commercial versions of the same DJ tables. Of course, this has

been outpaced by Surface 2, but that technology is not currently

DIY accessible. I don't plan on doing something for DJ'ing, but

just general experimentation.

Aquarium LED Lighting

LED lighting has come a long way. It's generally more efficient

than even fluorescent lighting like the T5 HO units I use on my

current aquarium. LED lighting also provides a more pleasing

shimmer effect in the water. Here's a nice

write-up of DIY LED lighting on the Reef Central forums.

Aquarium CO2 and Lighting Automation

Speaking of aquarium projects, I'd like to create a .NETMF

automation solution for the new tank in my home office (when

built). It would be awesome if it could take readings from the

water at regular intervals, and adjust CO2, lighting, or other

additions as necessary.

Home-Made Analog Synthesizer

I have a number of interests here. I'd like to create a real

analog synthesizer, using .NETMF to handle patch management and

editing and the overall synth operating system. I have one simple

DIY synth board

that will help me get started initially, letting me work on an

operating system and user interface rather than get hung up in the

sound-producing logic. Eventually, I think I'd either expand on

that, or replace it with custom hardware.

That's the current list. I'm sure I'll remember a bunch of other

projects once I actually post this. :)