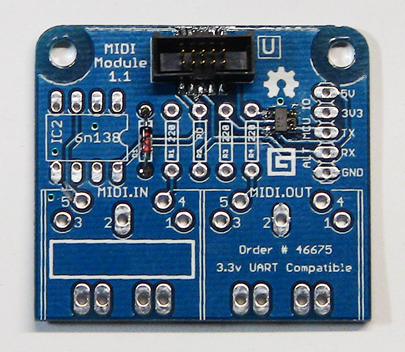

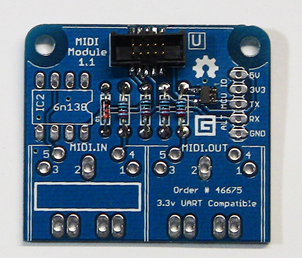

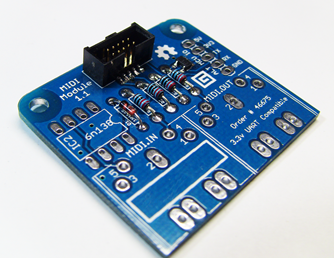

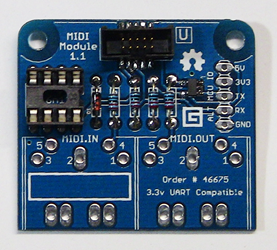

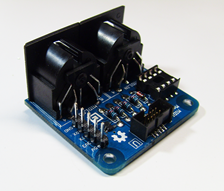

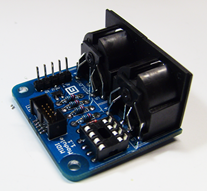

This module implements a basic MIDI In and MIDI Out interface

for 3.3v to 5v microcontrollers. MIDI is a 5v protocol, so special

steps were taken to step up the voltage on output, and step it down

(if 3.3v board) on input. This module includes a specific .NET

Gadgeteer-compatible 10 pin connector for use with .NET Gadgeteer

mainboards and the

Netduino Go, as well as a 5 pin .1" standard header for use

with other boards such as the Netduino classic, Arduino, AVR, FEZ Panda and

others.

If your board is a 5v board, expecting 5V signal levels

on inputs, tie the +3.3V and 5V lines together to the 5V

source.

Update 4/2/2012: Ordering information

is now at the bottom of this post for kits as well as for

fully assembled modules.

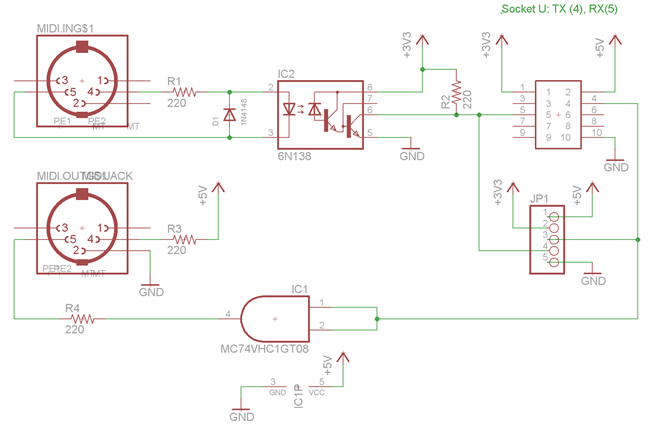

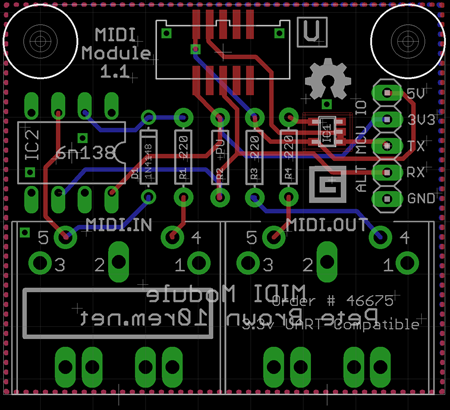

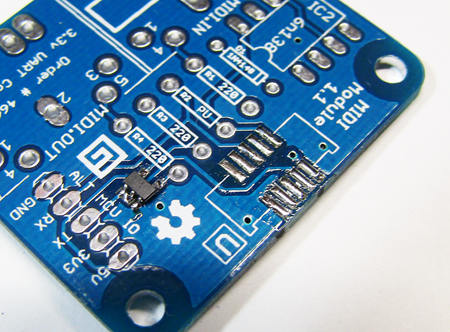

Schematic and Board Layout

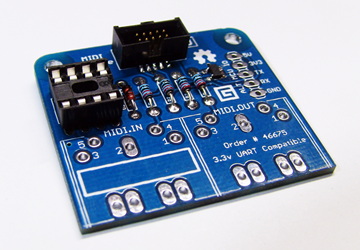

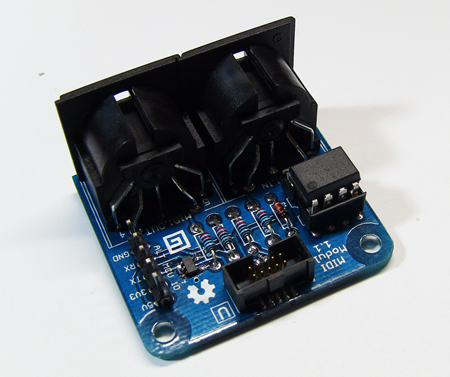

Following standard MIDI interfacing practices, the board uses an

optoisolator (a 6N138) to help prevent ground loops on MIDI IN.

Note also that the MIDI IN Jack is not grounded to the board. This

is also per MIDI specifications.

Blue traces are on the bottom of the board, red are on top. Both

layers are flooded with a ground plane so you won't see any of the

ground traces here.

R2, the pull-up resistor, is explicitly labeled on the

silkscreen using "PU". I have found 220ohms to work fine with the

boards I've tested it with. If you're trying a board with different

pin characteristics or pull-up requirements, you may want to use a

different value, such as 470ohm, or even as high as 10k.

Parts List

If you decide to have the board made yourself, you'll need a

number of parts. I've included links here for each of the required

components.

| Quantity |

Part (via Mouser unless

otherwise mentioned) |

Description |

| 1 |

863-M74VHC1GT08DTT1G |

ON semiconductor. TTL-level gate. |

| 2 |

806-KCDX-5S-N |

5 pin DIN PCB mount MIDI connector (these

similar ones from Sparkfun also work) |

| 4 |

270-220/AP-RC |

1/8w (small footprint) through hole

metal film resistor. 220 ohms. Typical 1/4w are slightly too big

for the board. |

| 1 |

512-6N138 |

6N138 High Speed Optocoupler. DIP-8

package |

| 1 |

|

(optional) 8 pin DIP IC socket |

| 1 |

512-1N4148 |

1N4148 through hole small signal diode

(any manufacturer is fine) |

| 1 |

Get through GHI |

10 pin Gadgeteer Socket |

| 1 |

Get through GHI |

Gadgeteer 10 pin flat ribbon

cable. |

| 1 |

|

Optional 5 pin header (male or

female). Standard .1" spacing. |

| 1 |

MIDI Module PCB Board |

From me, or have manufactured

yourself |

Of all the pieces, the key ones not to substitute are the ON

Semiconductor TTL-level gate, and the 6N138. The TTL gate is used

for level shifting a 3.3v signal to a 5v signal for MIDI out. This

is required to support 3.3v MCUs. I haven't found a suitably small

through-hole version. Most are 14pins or more, making the board

much larger than it would need to be.

The 6N138 has been tested and has proven itself again and again

as the most compatible of all optoisolators. MIDI equipment can be

old and therefore very finicky. I do not recommend substituting

this part, but as it is socketed, you can try others if you

wish.

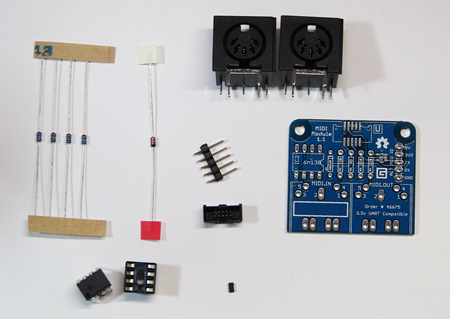

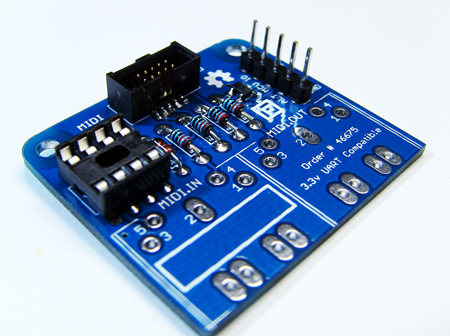

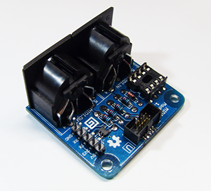

Here are the parts that make up the assembly:

The parts may look slightly different, but will be equivalent

(for example, some of the 1n4148s I have have slightly shorter

leads). Not shown is the Gadgeteer 10 pin flat ribbon cable. The

tiny part is not a tick, it's the ON Semiconductor TTL gate.

Unless you explicitly request otherwise, this will already

be soldered to your board when you get it.

That's a shot of the first round of parts for this kit. An ammo

box of 220ohm 1/8w resistors, a tube of optoisolators, a tray of

MIDI connectors, and a tape of TTL logic gates.

Tools Needed

If you've soldered boards in the past, you should have

everything you need. Here are my recommendations:

- Soldering iron. Preferably one with a good temperature control.

The Hakko FX888 gets great reviews. I have a Weller WESD51 with a small screwdriver/flat

tip. My dream setup would include a Hakko FM203 with two different irons.

- Solder wick to help with any screw-ups.

Optional, but helpful. If you buy some, get the good stuff, not the

cheapo wick. Cheap wick burns your board more than helps.

- Solder. I use Kester 66/44 .020" RA rosin-core for soldering

all but the largest components, and the .031" stuff for the bigger components.

Whatever you're used to using should work, but I strongly

discourage using big fat solder wire.

- Optional: I've found that a rosin flux pen helps with the

surface mount connector and the TTL logic gate. Use a flux that is

compatible with your solder. I use Kester #186.

- Optional: Flux cleaner. Rosin-core flux can be left on the

board after soldering. It's not super pretty, but it hardens into a

plastic-like substance that keeps the acids locked up. If that

still bothers you, before you put the optoisolator chip in place,

you can use a good flux cleaner on the board. There are any number

of them that will work. Here is one. Clean in a well-ventilated area,

and make sure the board is completely dry before you apply any

power.

- Side cutters for trimming the leads.

- Optional: Tweezers.

Knowledge is Power

If you haven't soldered before, or you haven't soldered much, I

highly recommend the following soldering tutorials by Dave at the

eevblog. Watch them before continuing.

Soldering

tutorial: Parts overview. Good to watch if you are just starting

out.

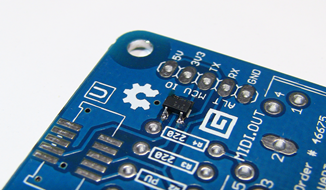

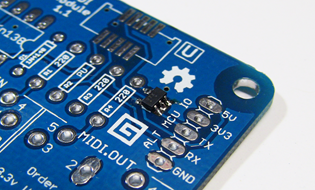

Step 0: The TTL Logic Chip

The first step is to solder the TTL Logic chip. Unless

you've requested otherwise, this will already be on the board when

it arrives.

When soldering little guys like this, I usually wear a

magnifying visor and hold the chip in place with a pair of

tweeters. I then bring a tiny blob of solder over to one of the

pins just to tack it in place. I then, using a tiny bit of solder,

fix each other pin in place before returning to the tacked pin to

clean it up. Don't heat this guy up too much. Also, be careful not

to lose this tiny part. I don't have spares, but you can get them

via Mouser using the link in the parts list.

Take a look at the schematic and the board layout. Two

of the three pins closest to the ALT MCU IO header are supposed to

be bridged. Looking directly at the three pin side, the

left two are the ones that should be bridged. They may be bridged

just at the circuit board level, or both at the pin and board

level. Either is fine. Why bridged? That's because I use this AND

gate as a simple voltage translator. Bridging the two inputs

means 1 AND 1 = 1 and 0 AND 0 = 0.

Make sure each of the pins has a good connection with the board

and other than the noted pins, none of the others are bridged.

If this chip is not soldered correctly, MIDI out will not

work.

Step 1: The Gadgeteer Socket

The next component to solder is the Gadgeteer socket. If you're

not using this board with the .NET Gadgeteer, you don't have to

worry about soldering this socket.

This is a surface mount component, but it has fairly large pins,

and I've extended the pads to make it beginner-friendly. In any

case, an eye loupe, magnifying glass, or magnifying visor will come

in handy when checking the connections here.

The notch on the socket points inward to the resistors and the

rest of the board.

Update 4/16: I have a

more thorough tutorial for soldering these sockets now avaialable

on my blog here.

If you have a flux pen, put a little flux on all 10 pin pads as

well as on the bottom of the socket pins themselves.

I've found, for first-timers, the easiest thing to do is

to melt a tiny blob of solder on to the iron tip, and then rub it

across ONE of the 10 pins here to tin it. You'll end up

with a little mound of solder on that one pad. In the photo below,

I tinned all 10 pads. This is what I used to do. You can use

this approach, but after assembling a bunch of these, I've found it

much more difficult to keep the socket aligned. Tin just

one pad for the easiest assembly.

Then, holding the socket in place so that it lines up with the

silkscreened outline, press down on the one one pin to melt it on

to the tinned pad. This will tack everything in place. Ensure the

pins are all lined up. If not, heat that one pad and try again.

A small iron tip helps here.

Once everything is aligned, heat each pin and pad and solder

them so the solder just covers the pin. Be sure to go back and get

that first pin to make sure it has a good solder connection.

Remember, you not only need a good electrical connection here,

but also a good physical connection. This socket takes a fair bit

of abuse.

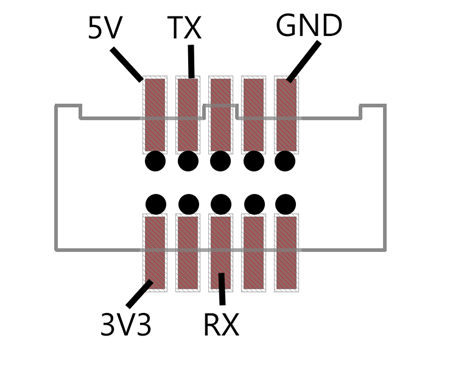

If you have a multimeter and want to do a continuity

test to check your soldering, put one probe on the pin in

the connector and the second probe on the labeled header pad on the

right of the board. You should find the pins as follows. (Oriented

just like the board in the photos. Mounting holes at the top)

Double-check your joints here, preferably with a magnifying

device of some sort. it's really easy to have a pin sitting on top

of the pad instead of soldered to it.

With that, all the hard stuff is done. Everything else is

traditional through-hole construction from this point forward.

Step 2: The Diode

Next up, the diode. Diodes are polarized. That is, the direction

in which you install them is important. One end of the diode will

have a black line (more likely a smear). Align that with the white

line on the silkscreen as shown in this photo.

Quickly solder the diode. You don't want to linger and burn it

up, but you don't have to race either. Make sure you get enough

solder on so you have a nice small but correctly shaped fillet on

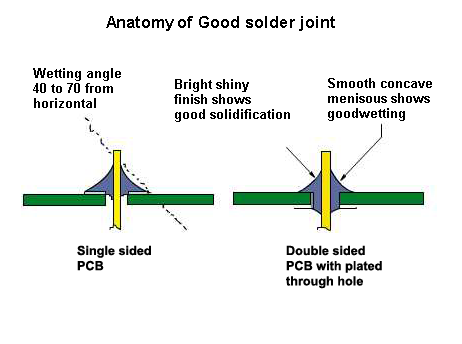

the bottom as well as on the top. A proper solder joint should look

like the double-sided PCB example shown here (board is upside down

in the diagram)

(the image links to the source. There are lots of soldering

tutorials out there. Refer back to the ones in the opening if

you're not sure.)

Snip off the excess lead, being careful not to cut into the

solder fillet itself.

Step 3: The Four Resistors

There are four 220 ohm 1/2w resistors. These are a smaller size

than the usual 1/4w resistors you may be used to, but they solder

exactly the same way. There's one resistor, R2, which is marked on

the silkscreen as a pull-up. 220ohm has worked for every board I've

tested, but if your microcontroller needs a stronger pull-up,

replace that with a 470ohm or even 10k ohm resistor as required.

Get the 1/8w smaller ones if you can, as the larger 1/4w resistors

won't quite fit without putting them in a bit crooked (and we don't

pass anything close to 1/4w anyway).

Resistors are not polarized; you can put them in in any

orientation, but your board will look more professional if the red

lines all line up :)

That's it for all the low-profile components. The next step is

the IC socket for the optoisolator.

Step 5: IC Socket for the Optoisolator

You could solder the optoisolator directly on to the board, but

these are sensitive little guys. Inside, there is an LED and a

couple transistors, none of which would be good to fry. These chips

also cost almost a dollar each in large quantities, so it's better

to use a socket.

Orient the socket so the notch is lined up with the notch on the

silkscreen (pointing right in the photos below)

The next step is helpful if you will be debugging or using the

board with non-Gadgeteer devices.

Step 6: Optional Breakout Pins

Install the 5 pin header. The easiest way to do this is to use

your thumb to hold the pin header to the board while it is flipped

over. Keep your thumb away from one of the end pins. Bring a blob

of solder to the pin your thumb isn't touching, and tack it to the

bottom (wipe the solder across the pin and pad), making sure the

pin header is perpendicular to the top of the board. If all looks

good, solder the remaining pins and then go back and fix up the

solder joint you tacked.

Next up: the final soldering step. MIDI sockets.

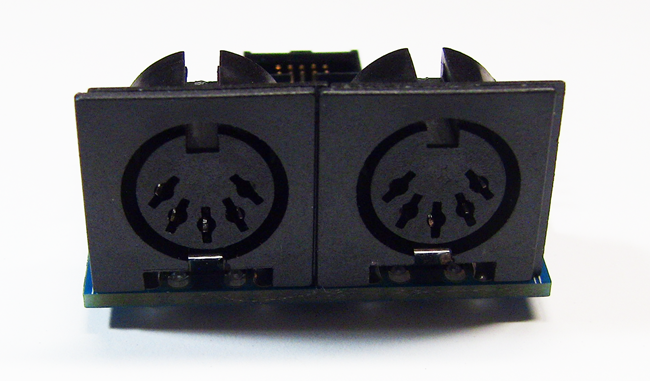

Step 7: MIDI In and Out Sockets

We're just about there! Next, put the two MIDI sockets on the

board. They should fit tightly with the faces overlapping at the

little notch. These should stay in place with just friction, so no

need to tack them in place unless you managed to get a socket with

undersized pins.

Use a fair bit of solder on these pins. MIDI sockets take a lot

of physical abuse. Take care to make sure, at least on the ground

and data pins, that you have good solder fillets both on the bottom

and the top. The solder pads nearest the edge of the board are

there just to help take the stress of insertion and removal.

Step 8: The Optoisolator

The final hardware step is to insert the optoisolator chip. Line

the side with the dot or notch with the notch on the silkscreen and

the socket. In most cases, you'll need to bend the pins inward a

little before inserting it in the socket. The easiest way to do

this is to grab the chip by the ends and slightly roll it on a hard

surface like a table top. Don't over bend, but make sure the pins

will go cleanly into the socket.

Also, the optoisolator is a static-sensitive device, so no

scuffing around on the carpet while you mess with this chip!

You're done! The next step is to load up the software and sample

program and try it out on your own device.

Troubleshooting

MIDI In doesn't work

- Check Gadgeteer socket (continuity test as described above is

easiest way)

- Optoisolator socket not properly soldered, or chip not

correctly inserted

- Check resistor solder joints

- Check MIDI Input socket solder joints (remember, they need to

have a bead that extends to the top of the board)

- Diode in backwards

- Diode burnt out

MIDI Out doesn't work

- Check Gadgeteer socket (continuity test as described above is

easiest way)

- Check MIDI Input socket solder joints (remember, they need to

have a bead that extends to the top of the board)

- TTL Logic chip not properly soldered

- Check resistor solder joints

- TTL Logic chip burnt out (unlikely, but possible)

What to use it with

Wait. You don't have any MIDI devices in your

studio/office/garage? Check out some of these inexpensive, but very

cool, kits and sound modules.

Pricing Ordering Information

NOTE: As of 5/9/2014, both the kits and assembled

modules are out of stock. If there is sufficient interest for

another run, I will do so. Please email me with any questions or

suggestions. Also, if there's interest, I'm considering building

more functional and intelligent MIDI interfaces which include

things like timing/clock on-board, so they aren't affected by

.NETMF timing considerations.

The kit is $16 for the kit with a Gadgeteer socket

connector.

Shipping -- I always use current USPS rates. At the time of

writing, they are:

- Boxed Priority mail shipping anywhere within the US is a

flat $5.80. (I can fit several kits in the same box for the

same flat shipping fee, should you want more than one.)

- Canada and Mexico ship USPS Priority, boxed for

$19.95.

- All other countries are $23.95, USPS Priority, boxed.

Fully assembled modules are $26 plus the same

flat rate shipping. These take just a little bit longer to send out

to you, and may or may not use a chip socket (I may substitute an

SMD version of the optoisolator, at my discretion)

You probably already have spares, but add $2.50 if you want a

10cm Gadgeteer ribbon cable. I just get these

from GHI in packs of 10, and sell them at cost as a

convenience. Depending upon my own stock, this may add a slight

delay to the order.

Payment via PayPal. (I'll send you the paypal address when you

contact me)

Contact me if

interested.

Module Drivers, Source Code, Schematics and More

All the driver code, installer, board layout files and more are

available on my CodePlex site: http://petebrown.codeplex.com/