As a geek, there are a number of milestones or rites of passage

for children:

- First drawing of any vehicle with more than three guns

- First original LEGO model

- First time you figure out how to turn on the Xbox and get into

a game without help

- First time you solder something

- First program written

- First cosplay at a geek convention

- First computer you build from parts

- First date with someone who tolerates nerds or even out-nerds

you

There are many, many more, especially depending upon the class

of nerd/geek. Anyway, you get the picture. :)

My son sees me solder things all the time, and has always been

interested. However, a soldering iron is something that, like your

first pocketknife, requires a level of respect and

self-preservation when using.

Tonight, I felt he was ready for it, so we worked on his first

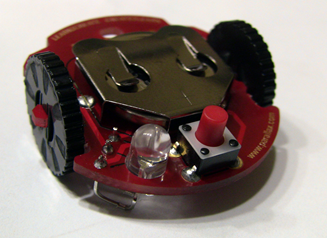

soldering project. The kit chosen is the Parallax S2 Robot Badge. This is a nice little

"learn to solder" kit which gives you something interesting at the

end: a model robot with a button that you press to make an RGB LED

cycle through colors.

There are lots of other "learn to solder" kits, but most of them

are more like practicing your writing by repeating scores of the

same letter on a page until your hand cramps up; at the end, what

you have to show for it is hardly inspiring and not even remotely

interesting.

This kit has a grand total of nine solder joints, including some

challenges:

- LEDs are easy to burn out if you heat them up too long

- The large metal battery holder is a giant heat sink, so it

takes a totally different soldering style.

- All the joints are small with relatively small solder pads

(except on the opposite sides .. the large pads on on the wrong

side, oddly)

But, what you get out of it at the end is this:

And more importantly, this:

Note that I did only one solder joint myself. Ben did the rest,

including clipping the leads, all under my close supervision. The

only thing he needed me to do was push the wheels on because

they're a pretty tight fit (note that they don't rotate).

Before building this, I showed him how to solder using a

resistor and a broken PCB I had. I did one side, he did the other.

That was the only prep other than discussing the safe use of the

iron (never take your eye off the tip, always place it in the

holder when done, never get distracted, never drop it or put it

down on the table, etc.)

All in all, a very worthwhile experiment that he showed

surprising aptitude at.

If you're looking for a good kit to use to learn to solder, this

kit, plus a fine tip iron and fine solder, is a really good choice

and a very fine geek bonding moment.