In early September 2004 on a Friday afternoon of a vacation day,

I paid a visit to Lowes to pick up some plumbing supplies to fix

the kitchen sink. As always, I wandered over to the tool department

to ogle over the wares - something made much easier now that they

opened the tool department up rather than keeping it walled-in.

While in there, I saw a neglected-looking Delta contractor's saw

marked at $280. I noticed that the top had some minor rusting and

scratches, and the fence was broken. I wrote down the model and

serial number, quickly went home and did some research. Then I

fixed the sink. My priorities were, of course, in good order

:-)

The tablesaw, model 36-430, turned out in the reviews to be the

Lowes version of the 36-440 and 36-444. The reviews were pretty

good, with the only negative comments being the occasional beef

about the fence not being as good as a Biesemeyer, and the motor

not being as powerful as a UniSaw. Given that it is a $700 (in

2000) contractor's saw, comments like that were to be expected.

I figured I'd sleep on it and visit Lowes again in the morning,

but I thought better of it after a little bit; Saturday morning at

the local Lowes or Home Depot is never fun. So with less than an

hour until closing, I picked up a trusty straight-edge to check the

table, and some tools for disassembly, and rushed back to Lowes to

check on the saw.

When I got there, after checking the cast iron for flatness (it

was as flat as I could measure) I took a much closer look, and

realized that the motor was missing! I asked the nice older

gentleman there if the "as is" price meant no motor. He thought the

motor was in the unit, but I showed him where it would normally

attach on the back of the saw. He called over another older

gentleman who said "What, no motor? Put $100 on it". I then pointed

out that the fence had no handle and was cracked, and that there

was a handwheel missing from the side. He said to the other

gentleman "Ok. put $50 on it, and make sure it says 'Frame Only'".

I told him for $50, I'd take it right then!

So I ended up with basically a saw body, trunion and guts, and a

cast iron table top for $50. To see what I did with that, read

on.

The saw I really want is a Mini-Max 8' sliding table saw

(such as the SC-4W

8' or the SC-315WS).

However, In order to get one I'll need to build a larger workshop.

As that isn't happening any time soon, this little saw project

saved me from having to worry about it for a bit. I have a Mini-Max

16" bandsaw coming in January 2005, and I can't wait for that. In

fact, that bandsaw is what drove me to get going wiring the shed

workshop for 240v service. As an aside, this is the jointer/planer

I intend to get before I get another saw: MiniMax FS

350

If you find the information on this page useful or interesting,

please take a moment to sign my

guestbook. Thanks!

1. Cleanup and Inspection

Overview

I took the saw apart in the parking lot at Lowes so that I could

get it in my wife's CRV (she had mine on a trip to the West

Virginia/Ohio border to get some native plants

from a friend. The tinted windows were necessary to keep the plants

from getting toasted)

One thing I can tell you about this saw - it was really dusty.

No one dusts the equipment in the tool department at Lowes. It's a

shame that no one takes care of anything there, but I guess that's

what is to be expected. When I want to see clean tools in a nice

setting, I take a trip up to Woodcraft.

The saw included the following:

- Base with dust "ramp"

- Splitter and blade guard (typically something the owner

replaces in short order)

- Standard steel saw insert

- A broken fence

- A serviceable but unfriendly miter gauge

- Two pressed-steep extension wings

- Front aluminum split fence rail

- Back steel split L-angle fence rail

- Power switch assembly

- Trunion, arbor, pulleys and related pieces

- Cast iron top

- Blade angle handwheel assembly

- Inexpensive Delta steel blade

Importantly, it was missing the following

- Motor

- Motor mount

- Motor pulley and pulley guard

- Drive belt

- Blade height handwheel assembly

- Wrenches

- Owner's Manual

The following was supplied, but broken

All in all, I think it was worth $50, if not more. I had already

made up my mind that I would probably not keep that fence, and

definitely wouldn't keep the miter slider. The missing motor and

belt would give me an opportunity to upgrade some items that I

probably would have left alone.

I wasn't concerned about the missing wrenches or manual. The

manual was easily found on Delta's web site. The wrenches happen to

be the same as those used on my Delta compound miter saw.

I wasn't aware of the missing motor mount util I got home and

started going through the online parts list. I had originally

assumed that the motor just clipped onto the pins on the back of

the saw using a mount similar to the UniSaw.

The extension wings had duct tape or some other strange tape on

them. Since I hope to have a router table and regular extension

table attached to the saw, I was also not concerned about the

condition of those tables.

Oh, and just for proof, here's the shot with the price:

Cheap! Decent price for a half a saw. Pete Brown, September 5,

2004

Dusty Parts The base, blade guard and splitter, insert and fence.

Pete Brown, September 5, 2004

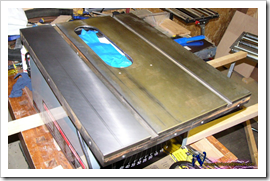

Saw The top, miter gauge and one of the two extensions included.

Notice the split fence rail. Pete Brown, September 5,

2004

Fence Broken fence cam and handle. Pete Brown, September 5,

2004

Dusty Blade Dust everywhere! That blade has never seen the light of

day or the bite of wood. Pete Brown, September 5, 2004

Pulley and Arbor The standard two-piece split and cast arbor

pulley. Pete Brown, September 5, 2004

Energy Efficient! Missing motor mount and motor. Pete Brown,

September 5, 2004

Reconditioning the Top

One of the first things I worked on with this saw was the top. I

hate to see a dusty, gummy, rusty cast iron top on a tool. Given

the humidity of the area, any rust on it was only going to get

worse, so I had to clean it up and protect it sooner rather than

later.

Before The cast iron top before any work was performed on it.

Notice the rust where the iron was attached to the fence and

wings.Pete Brown, September 5, 2004

The top of the saw had some scratches, some rust, and a decent

amount of pre-rust oxidation and grime. Luckily, the only real

areas where the rust took hold were on the sides of the table and

in the miter gauge slots. The scratches were from the crummy old

miter gauge and the fence, neither of which ran on any type of

stand-off. The miter gauge in particular had a worn spot on the

bottom of the cast iron from everyone and their brother walking

past the saw in the store and moving the gauge back and forth.

Nevertheless, the scratches were almost entirely cosmetic. Once

I cleaned up the table and waxed it, it was very smooth. There are

a two or so little nicks near the edge of the table, but nothing

that would make me want to return it. hehe.

Left Side Done Note the taped-in paper used to protect the interior

from the top cleaning. Pete Brown, September 5, 2004

To clean the table I started off by using the Boeshield products

I have. I have found, however, that those tend to leave a bit of a

stain (more like a dull spot) on the surface if you don't clean

them off right away. I think the stain is from the acid in the

product eating into the cast iron top. My wife said the product

smells just like the grout cleaner she uses around the house -

maybe it is the same stuff. In the end, I had better results by

soaking the table top with WD-40 and then wet-sanding it with fine

grit wet/dry sandpaper. To get into the miter slots, I used a

rubber molding sander (made for sanding curves on convex routed

edges), wrapped the wet/dry around that and slide it in the slot

until they were free of rust. It wasn't the best solution, but it

was something I had, and it worked fairly well.

Almost Done The top cleaned but not yet waxed. What an improvement!

Pete Brown, September 5, 2004

Once the table was clean and dry, I applied a few coats of

Johnson paste wax to the top. This helped to fill in any remaining

nicks, and left the surface shiny and smooth. Once everything is

assembled, I'll add another coat or two for good measure.

To protect the saw's new top, I keep a soft dry old bath towel

on the top when the saw is not in use. This keeps dust off, but

more importantly, also keeps the moisture from settling on it.

2. Replacement Parts

I went to the Delta Woodworking parts and owner's manuals site

and found the parts list for the table saw. I looked the saw over

and decided that I would need the following replacement parts:

- 1086491 - Handwheel Assembly

- 422-19-138-0003 - Knob for Handwheel

- 49-034 - Belt (not purchased)

- 926-01-041-9366 - Motor Pulley (2 1/4" OD) including set screw

(not purchased)

- 422-02-089-0005 - Motor Mounting Plate

- 34-965 - Belt & Pulley Guard including all pieces and

hardware

- ?? - 120v Motor Pigtail

I quickly found out that Delta replacement parts are absolutely

not cheap. I already had the wrenches I'd need (one of which came

with my Delta miter saw), so I didn't bother spending another $25

on those.

I then spent several days trying to find suppliers of parts on

the net. While there were many listed on the Delta site, the

majority did not list or carry replacement parts. In the end, I

found only two sites that sold Delta replacement parts: Ace Tool

Repair and Tool Parts Direct.

Of the two, I ended up going with Ace Tool Repair as they had

a better selection, and despite being located in Canada, were

cheaper even with the more expensive shipping. I think the

$0.77/1.00 currency conversion rate helped a bit. The people at Ace

Tool Repair were also a pleasure to work with.

The parts shipped out to me around 9/17/2004 and arrived prior

to the end of the month. That was actually quicker than I thought

it would be.

3. Belt and Pulley Upgrade

Rather than waste $40 on the Delta cast iron motor pulley and

drive v-belt, I hopped up to the semi-local Woodcraft and bought

their Contractor's Saw Upgrade Kit for $54. That kit included two

machined pulleys, and a nice quiet link belt. Many people upgrade

their saws with these parts anyway. Since I needed the part, I

decided to go with the best I could find, just as I did with the

motor itself.

Picture Info Pete Brown, September 11, 2004

Picture Info Pete Brown, September 11, 2004

Price paid $54 in-store, plus tax.

4. Motor Upgrade - Baldor L3515M

Delivery

Cocoon The new motor as-delivered. The plastic caused a little of

the paint to flake off. Pete Brown, September 11, 2004

I ordered the replacement motor from Amazon.com Toolcrib.

Toolcrib had the best deal - the price was right to begin with,

then they took $25 off for the order being over $199, then the

shipping was free. The shipping is what will kill you with most

other stores, considering the package weighs over 50 pounds. This

is not the kind of item you're likely to find in any local stores;

at least I couldn't find anyone who carried it.

A little aside on various stores. Amazon Toolcrib has been very

good to me. I've shopped around a lot, and for the types of

products you might get at Lowes or Home Depot, plus some of the

more specialized products, they can't be beat. They certainly don't

list everything, and I find myself hitting up Woodcraft (the local store in

Towson), Rockler or WoodPeckers, but when they do,

they generally have the best deal, especially when shipping is

factored in. I ordered my Jet 12" disc sander from them a while

back, and it too had free shipping. The thing must have weighed 100

pounds! Woodcraft has a decent selection, but they are almost

always priced way above anyone else. They're good on sales, and for

in-person browsing of the store. Rockler has a lot of specialty

items, but I've found that getting things from them at a

woodworking show will be the best deal by far. WoodPeckers is great

for Incra items and other things a person upgrading their saw might

be interested in.

If there were more woodworking stores near me, I'd definitely

patronize them. Unfortunately, Woodcraft is about it. As much as I

like browsing their store, and picking up items, I just can't

justify the big purchases with them unless they're having a great

sale. Often times I do buy things from them and pay more than I

would at toolcrib because I appreciate that they have a store I can

browse and get that instant gratification of the purchase.

Unwrapped The motor unwrapped. Notice the mounting hole pattern.

Pete Brown, September 11, 2004

Baldor motors are recognized as being some of the best in the

industry. The Baldor L3515M has the correct mounting flange, the

correct arbor size and HP within the range I wanted. The stock

Marathon motor originally included with the saw was 1.5HP at 115

and 2HP at 230V. The new Baldor motor is 2HP, and will also work at

both voltages. I do intend to run it only at 230, however, once I

get the wiring completed.

Price paid : $254, no tax or shipping.

Installation

I installed the motor on the saw on October 2, 2004. The

roughest part about mounting the motor is holding it up while you

try and attach the plate to the rest of the saw. The motor is

pretty heavy. I found that propping it up with a 2x2 of appropriate

height made things easier.

Rather than pay $1.00 to $2.00 each for the "Delta" bolts, I

just went down to the local Lowes with my Delta parts sheet and

paid around $0.06 each for the correct types of bolts, nuts and

washers.

Installed The motor installed on the back of the saw. You can also

see the new link belt and the motor pulley cover. Pete Brown,

October 3, 2004

One of the difficulties with this motor comes about due to the

flexible mounting holes. The motor does not automatically square to

the mounting base like it would if it had simple round holes. This

additional flexibility is definitely a plus, but it also makes it a

bit more work to square up. Of course, you should mount the motor

to the plate itself on a flat surface, not while it is attached to

the saw.

Lacking any better ideas, I squared the motor to the mounting

plate itself by mounting it as far back as possible. I will

resquare this shortly, as I have noticed that it is not 100%

correct. The stress from the belt torqued it just a bit.

One other thing I noticed is that the link belt is just couple

links too long. When the blade is at mid height, the motor rests

all the way down on the mounting arm so that the mounting plate is

actually contacting the arm. This causes too much slack, and

therefore vibration, in the belt. I'll tighten this up when I do my

final squaring.

Clearance Check It is important that the saw not stick up above the

table top when the arbor is at 45 degrees. There is about 3/4"

clearance here. Pete Brown, October 3, 2004

A note on wiring: the motor must be wired (per instructions) in

reverse due to the way it is mounted on right-tilt Delta

contractor's saws. Happily, this is a very easy thing to do. It may

be tempting to plug the motor in and try it with no load. From

experience, I recommend not doing that. With no load at all (no

belt or arbor pulley), the saw drew enough amps to put the lights

out in my shed (about 20 amps) briefly while it spun up. It did not

pop the breaker, however. Once I have the shop wired for 240v

service and more amps this fall/winter, I'll rewire the motor. In

the mean time, I'll be careful not to stress it with any difficult

or long cuts.

After I mounted the motor, I checked the clearance with the top

of the table. It is important that the motor not protrude above the

top of the table. If it does, you will not be able to properly

clear any sheet goods or wide stock when ripping or cross cutting

45% bevels. It is also important that the motor clear the fence

rails. Since I do not yet have my fence in (it will arrive the week

of October 4th), I could not check that.

Note that I will need to re-check the clearance once I remove

the couple links from the link belt. Also note one bad thing about

contractor's saws: the motor location effectively limits what types

of outfeed support you can have. Any outfeed tables need to either

stop short of the left of the saw, or be thin enough in at least

that part of the table that they will not be hit by the motor.

5. Miter Gauge Upgrade - Kreg Precision Miter Gauge

Picture Info Pete Brown, September 11, 2004

Picture Info Pete Brown, September 11, 2004

Price paid: $135.99 plus tax at the Woodcraft bag sale (anything

you could fit in their bag at least 50% was discounted 15%)

6. Fence Upgrade - Incra TSLS from Woodpeckers

The price of a new fence head from Delta is over $120 just for

the basic fence that the saw was delivered with - that doesn't

include the handle and other hardware. I wasn't in love with the

fence to begin with, and that price made me definitely decide to

write it off. So now I have a good excuse to look at some nice

replacement fences.

The current leader in the fence race is the Incra LS Joinery

Package. I have to take some measurements, however, to see if

that will even remotely fit in my workshop. The LS-Positioner has

an arm that extends out roughly 42" from the fence position. If you

have the fence all the way to the right, that means you need

another 36" (roughly) of clearance to the right of the end of the

rails.

The Incra has several things going for it:

- Best accuracy in the industry

- Perfect (within tolerance) repeatability of settings

- Attachments for additional jigs and fixtures (this is very

appealing to me)

- Ability to easily use with an attached router table (included

in the package)

Another option is the Incra

TS-IIIa (TS-III reviewed, the "a" model has a machined, not

extruded, fence.). That is far less expensive than the full Joinery

system, and can use the router

Incra WonderFence to make it almost the same as the LS Joinery

System. The main difference, however, is the way in which the fine

adjustments are made. I can always get the LS without the full

joinery system. I am not yet sure which one is best. I think the LS

(lead screw) version would be better, and more precise. I will be

looking into it soon.

For economic reasons, what I will likely end up doing is getting

the TS-LS basic system and then later adding on a WonderFence and

router table. It will cost a bit more in the long-run, but it

allows me to use my saw earlier.

A Biesemeyer wouldn't be a bad alternative. However, the Incra

really is what I want. In fact, I have my workshop in the old CAD

program to see how to fit it all in. :-)

Decision

In the end, I decided to get the full 32" Incra TSLS system from

Woodpeckers. This package includes everything a guy could want,

including the LS Positioner tablesaw system, a router table for the

left wing on the saw, a router insert plate, the Incra WonderFence

and Joinery system, including templates. I upgraded to the aluminum

router insert, and also picked up a project book at the same

time.

I did not order any right router table, as that would be

difficult to use in my small shop. Instead, I plan to build an

extension there with storage underneath. I do not plan to use the

steel wings that came with the saw. I have one installed only

temporarily.

I ordered the package on September 30, 2004 in the morning. All

the boxes shipped the same day and arrived in just a few days. To

see my review of this system, visit my

Incra TSLS Review Page

7. Guard and Splitter Upgrade - Undecided

Having seen the European riving knives in action, anything less

is just a compromise. Since you can't put a real riving knife on an

American saw (due to the way the blade rotates when it is lifted),

I'll have to find the next best thing. Due to my selection of

fence, I can't use the included splitter without cutting the rear

Incra fence rail. There's no way I'd do that just for the nasty

stock splitter!

For the splitter, I am currently leaning towards the Biesemeyer

splitter. At $107, it's awfully expensive for what it does,

however, and also does not support thin-kerf blades. In the mean

time, I'll likely just slice up the splitter that came with the

saw.

For the guard, I'm looking mainly at overarm guards with and

without built-in dust collection ports. The Delta

Unigard ($270), while lacking dust collection ports, is a nice

unit with over-table power and tool storage. As a bonus, it

includes a servicable splitter. Between the larger motor and the

rear rail of the Incra fence, however, I don't think there would be

room for something like the Unigard. Once I have the fence

assembled, I will take another look. Other guards include the

Excalibur and the Exaktor. The Excalibur support arm might

interfere with the LS positioner on the Incra fence. TBD.

Update March 2007: I eventually ended up purchasing the

Excalibur guard and use the MJ-splitter from Micro-Jig. The plastic

MJ splitter is ok. A metal one would be better. I had the plastic

one fail and had a nasty kickback incident. The Excalibur guard is

nice, but suffers from not having brushes or something to surround

the blade. I will attach a soft-bodied baffle around the bottom

made either from brushes or leather or similar.

8. Bottom Line

| Item |

36-444*

Delta Contractor's Saw |

36-507X

X5 Delta Contractor's Saw |

The Frankensaw |

| Base American-Made Contractor's Saw |

700 |

975 |

50 |

| Replacement Parts |

0 |

0 |

120 |

| Motor Upgrade |

0 |

0 |

250 |

| Pulley and Belt Upgrade |

55 |

55 |

55 |

| Incra Fence and Router Table Upgrade |

850 |

850 |

850 |

| Kreg Miter Gauge Upgrade |

136 |

136 |

136 |

| Total |

$1,741 |

$2,016 |

$1,461 |

|

* The Frankensaw is based on the 36-430. This is basically the

36-444 as sold by Lowes. The manual has both model numbers listed.

The cost of the normal Delta saw goes up if the Delta saw owner

had replaced the motor. Since many owners do not do this, however,

I decided to leave that out on that side. The Current X5 comes with

a better fence than the 36-444 (a Biesemeyer). However, I still

find the Incra fence to be in a class of its own.

Also please note that you can get a Delta made overseas

(36-680), with a Biesemeyer-like fence a smaller cabinet and a

chute-less stand, for about $600. The same saw with a UniFence

(36-681) runs about $800. These prices were current at Amazon.com

in September/October 2004.

In the end, for about $300 less than the original saw, and

around $550 less than a currently available saw, I was able to put

together a saw with a more robust motor, all upgraded parts, and an

incredible fence. I did not save as much money as I thought I

might. In particular, the replacement parts were more expensive

than I thought. However, I ended up with a very accurate and

fine-tuned saw that I know inside and out, and which is made up of

some of the best parts I could find.