(project completed in 2001/2002)

One of the very first projects I decided to do when I bought the

house was to replace all the existing phone and cable TV wiring

with structured wiring. This was really quite a project, and

helped to familiarize me with all the little nooks and crannies of

the place.

If you are a technically-minded person (I happen to be a

software developer), or comfortable with running electrical wires,

running wiring like this through your house yourself is not very

difficult, and will save you a ton of money.

Important Note: Some time after I completed

this work, when I was investigating getting a permit for wiring my

shed for my woodworking tools, I found out that 1. It would have

required a permit and 2. Homeowners where I live are not allowed to

apply for the permit or do the work themselves. In Anne Arundel

County in Maryland, even though Home Depot and Lowes sell all the

"do it yourself" stuff locally within the county,

any and all electrical, plumbing or mechanical work must be

permitted and the permit must be pulled by a master electrician,

plumber, etc. Obviously the county is not interested in safety,

only in the lobbying efforts of the professional groups. If safety

was the concern, they'd let a homeowner (who is likely going to do

a lot of things like this themselves anyway) apply for a permit and

get the work inspected and approved. Instead, the homeowners will

do the work themselves anyway and can't get it inspected.

In this Maryland county, a homeowner cannot even legally

replace a sink trap, replace a breaker, or install a

battery-operated smoke detector themselves. Yet another

case of big money lobbying groups prevailing over common sense. In

any case, check your local codes before starting any work.

One thing that made this easier in my house, is that I own a

split-level house with a drop ceiling in the basement.

Because of that, it was really easy to run wires to the various

rooms without going through two stories of wall and ceiling.

I'm not sure how well I would have done if I had to run wiring

between, say, the first and second floor of a house with a standard

basement.

Each room in my house now has at least one wall outlet with 3

cat5e and two shielded coaxial jacks. This gives me the

ability to place televisions, cameras, phones, computers, smart

devices etc. in any room.

The computer corner of our basement has two such wall outlets

(one for each computer) and the television room has one outlet

behind the couch and a more comprehensive outlet behind the

television. The outlet behind the television is a double

outlet and includes wiring for surround sound speakers as well as

the usual.

This project took me several weekends to complete after my

initial research, material purchasing, and tool purchasing (an

aside: you spend a lot of money on tools that you'll likely never

use again. If you know someone in the business, try to borrow

the tools from them instead, or maybe try to get a used set of

tools).

I estimate that after tools and materials (not including labor,

of course), this project ran me about $1500 for my entire 2400sqft

house. (9 outlets, including one extra-capabilities outlet behind

the TV). That is significantly less than one would pay a

contractor for similar work.

Tools used

- RG45 Tool

- Punch down tool

- Basic Cat5e Cable Tester (essential!)

- Specialized wire cutters and strippers for cat5/5e cable

- Specialized wire strippers for coax

- Coax crimping tool

- Cable snake / fish tape

- Drill and various drill bits

- Stud sensor

- Coax wrench

- Dremel Tool (for cutting through drywall)

- Gloves to protect your hands from insulation

- Safety Glasses to protect your eyes from insulation and

drywall

- Paper dust mask to protect your lungs from inslation and

dust

- Baseball Cap to protect your head from insulation

In addition to all the connectors, outlets etc. you will want to

get a ton of black electrical tape, and at least as many different

colors of electrical tape as you have similar wires. For

example, I have three Cat5e cables per run, plus two coax, so three

different colors worked fine.

How I Pulled Cable at My House

Please keep in mind that I am not a professional electrician or

a cable-puller in the telecom industry. I'm just a guy who

did this in his house :-). Also keep in mind that my house

was already built and finished, and happens to be a split-level

with a drop ceiling in the basement. Typically, I had time to do

one room per day. That includes bundling the cables, cutting

the outlet hole, running the cable, and connecting up the outlet

jacks. It does not include the time taken at the end to

connect up the main wiring center or test the cable. Given

that, this is how I typically approached the install for any given

outlet :

- Plan the outlet location.To do this you need to take into

account several important things:

a) Make sure the outlet isn't near an electrical outlet, switch

or fixture. It should be a good eight inches or so away from any

electrical interference. You want to make sure there is no

electrical interference. When it comes to fluorescent lights,

it is typically worth it to run an extra x feet of cable simply to

avoid coming anywhere near the massive interference a fluorescent

light puts out.

b) Make sure you have a clean run from the wall outlet location,

through the ceiling or floor, to the central wiring location.

You want to make as few holes in floor joists as possible (and make

sure the holes are small so you don't weaken the joist).

c) Make sure the outlet is in a place close to where you expect

to use it! In my TV room, for example, I put a set of outlets

behind the television (with network outlets for things like TiVO,

online games etc.), and another set behind the end-table, as that

is where the telephone is typically located.

d) Make sure the cable run isn't going to follow close to a hot

water pipe. You don't want to melt your cable insulation.

e) Make sure there aren't any sharp bits of metal along the

planned route. This includes the bare edges of the suspended

ceiling supports. If there are sharp bits of metal, make a

note to avoid them, or grind them blunt with your Dremel

tool. It you simply tape over the sharp bits, the tape will

wear out.

- Cut the outlet hole. I found the Dremel drywall cutting

attachment on my Dremel tool to be the easiest way to handle

this. Make sure you put newspaper (taped to the baseboard

trim) on the floor to catch the drywall dust

- Insert the metal outlet mount in the wall. This is what

the outlet plate will attach to. I insert it before running

cable as it helps prevent damage to the nicely-cut outlet.

- Put a bit of colored electrical tape on each reel or box to

identify that box. Then, wrap the same color at the end of

each cable that you pull from that box or reel. It will help

if you put the color on the cable in about a foot or so from the

end. This is how you will identify which cable is which when

you get the cable to the destination.

- Wrap a good amount of electrical tape around the bundle of five

cables. Make sure they are not splayed-out at the end.

If you have a nice tight point, it will make running through the

wall much easier

- Feed out a little less bundle than you think you will need to

run from the outlet to the central wiring box/hub and tape it with

electrical tape every foot or two, neatly coiling it up on the

floor while you do so. The rig you see in the first photo

below is something I set up specifically to aid in this

operation. Taping and coiling neatly will keep the bundle

together, and help prevent snags

- Try to ensure you are setup in a way that will allow you to

pull the cable to the outlet using the fish tape. Select your

outlet location and feed areas based on this.

- Run the fish tape through the open area in the drop ceiling and

down (or up, if this is an upstairs room) to the outlet. To

avoid getting hung up on insulation, I would use pliers to crimp

the fish tape and closed, and would sometimes even use electrical

tape on it to ensure that it would not snag if backed-up. If

you can pull cable through non-insulated interior walls, you will

be that much better off. In general, I found it easiest to

run from an outlet, to the wiring hub, not the other way

around. A straightened coat hanger pushed around inside the

outlet hole can help you locate the end of the fish tape in between

the studs in the wall.

- Once you have the fish tape end sticking a couple feet out of

the outlet, you are ready to pull cable.

- Hook the end of the fish tape into the taped point on your

cable bundle. Make sure the cable is oriented in such a way

as to ensure that pulling the fish tape will pull the cable

point-first.

- Tape the bundle really really well to the fish tape. The

bundle is going to take a lot of abuse when pulled through the

wall, and you don't want to lose it! Also, make sure the tape

forms a nice taper from the fish tape to the bundle. Any

blunt end is going to get hung up either at the destination when

you try and pull it through the hole you made in the wall, or more

likely, in the insulation in the wall.

- Unless you like fiberglass splinters from your insulation, now

is when you want to put on some gloves and a breathing mask.

- Pull the fish-tape slowly. It can help here to have

someone else feed the cable into the wall. Stop pulling once

the cable end is sticking out of the wall several feet (enough to

make sure it isn't going to fall back inside the wall)

- Now is a good time to go grab a coke or something :-)

- Now you need to run the cable to the wiring location using the

route you decided upon in step 1. If you have a drop ceiling,

or an open-ceiling basement, this will help tremendously. Make sure

you secure the cable to joists with cable clips and zip-ties so

that the cable is not drooping and vulnerable to accidental

slicing. If you must cut into joists, make the cuts small -

follow the hole sizing and protection rules you can find in any

Home Depot / Lowes / Black & Decker "Do it yourself electrical

wiring" type book. While pulling the cable, make sure it does

not catch or wear on any of the holes you cut.

- Before cutting the cable from the reel, tape the colored

electrical tape around each cable in two spots : one just about 2

inches out of the wall, and one about a foot from there.

- When done, you should have a few feet of extra cable at the

wiring center, and two feet or so of extra cable at the outlet

end. You need to ensure you have a little slack, and enough

wire to strip more than once should you mess up on either end

:-)

- Start on the next outlet :-)

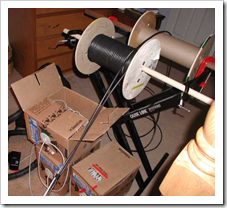

Here is a photo of the mechanism I used to make bundling wires

easier. As this photo was taken during the last jack

installation, the spools are almost empty. (Notice I have one cable

source/spool for each wire in my bundle. It is far too

cumbersome to try and save money by sharing a single spool across

two cables in the bundle. Because of that, I manually ran

half of the coax I bought onto an empty spool I picked up at the

wiring store.) Basically it is just a couple dowels held down

on keyboard stand using C clamps. I bundled the cables with

electrical tape as they came off the spool. If you want to do

this yourself, and do not have specific requirements, you may be

able to use the pre-bundled cable sets.

Notice that the front RG45 reel has yellow tape, the rear has

green tape. The individual Cat5e boxes have green, red and

blue tape on them as well. This is what uniquely identifies

each cable in the run.

Here is a photo of the shaft extension I used to drill through

the floor in the wall in the master bedroom. The master

bedroom wall is an outside wall that overhangs the lower level by

about two feet, so it was the most difficult installation in the

house. The way I made it work is I ran the fish tape through

the outlet location (a location that was selected because it is

near the open-ceiling area in the basement hot water heater

closet), and hunted for it in the basement. Not exactly the

most efficient way, but it worked :-)

Here you see the cable bundle being fed into the wall. It

took me forever with a cable snake to figure out where downstairs

the hole came out (remember the overhang, well that makes things

just a little difficult). This one outlet followed a

different pattern than the others. Instead of fishing through

the actual outlet hole, I opened up a hole close to the floor, and

ran the wiring through there. This was simply so I could get

the correct angle to drill the hole through the floor inside the

wall. Once the cable-pulling was done, I cut a hole above

this one, added the outlet and moved the wiring up through that

outlet. I then patched the hole and Melissa repainted the

patch :-)

Here is the wiring for a single Cat5e jack. If I am not

mistaken, this was taken before I changed from using the A wiring

scheme to the B wiring scheme. I rewired this one set of

jacks for this one outlet, and it was good practice anyway.

Notice the colored tape on the cable that indentifies this specific

cable.

Here is a rather poor picture of one of the many jacks that now

fill all the rooms in the house. My normal convention is to

treat the top Cat 5e jack as a phone outlet, and the other two Cat

5e jacks as network outlets, but that is by no means a

requirement. Due to the layout of the wiring center in my

basement, I can change those assignments around any time I

want. To keep the cables straight, I always put the Red Cat5e

at the top, followed by the Blue and Green below. (I'm a

computer-guy, so RGB was really easy for me to remember

<g>)

Here is the wiring panel recessed in the wall in the basement

"shop" room. The board (later painted white) above the panel

is removable to allow for access to the many wires that come into

the patch panels. For a more recent photo, select "About"

from the menu at the top.

Here is a diagram of the patch panel. My apologies for the

large image size, but the text was simply unreadable at smaller

resolutions. I never ended up getting SDSL, so the extra

(outdoor rated) cat5e cable was never used. Instead, I picked

up line-sharing DSL (ADSL). One of the nice things about this

wiring cabinet is that not only the DSL modem is located in here

now, but also all the ugly DSL line filter "dongles" that normally

would be attached to the wall on every phone in the house. In

addition, I later retired the Linksys router and purchased a

netgear ProSafe VPN router with eight 100mbit ports. The

Netgear router was far more reliable, and faster than the old

Linksys.

When I later put in the rack and upgraded to FIOS, I used a 14

port Netgear switch and the router from Verizon.