As software developers, we hear a lot about Open Source

Software. I'm a big fan of OSS, and think it's one of the single

most impactful things that has added to the collective knowledge of

the developer community. Microsoft has several larger open source

projects and software. For example, ASP.NET MVC is open source

software, and the .NET Micro Framework is a full apache-license and

community

contributed open source project (you can use our free Visual

Studio tools, or free and open source tools like Monodevelop to

code for it). Microsoft is a huge company; there are actually a

number of OSS projects going on and more every day.

Open Source means different things to different people, and not

everyone expect the same result of benefits from it. Phil Haack,

late of Microsoft, had a great post on the difference between Open Source

Software and an Open Source Project and an excellent follow-up

post on the spirit of open source.

On thing software developers are often not aware of, however, is

Open Source Hardware. It is to hardware as OSS is to software.

What is Open Source Hardware?

I have a few hobbies that center around making things. Some are

mostly physical/mechanical, like CNC machines. Others are mostly

electronic, like MIDI interfaces, synthesizers, MIDI to CV converters, and

whatnot. Most of these have code, firmware, which is (or will be)

released under Open Source licenses. But what about the actual

plans, schematics, and the board designs? How can you license and

categorize those?

That's something the Open Source Hardware movement is trying to

define and make easier.

From the wiki: (emphasis mine)

Open source hardware is hardware whose design is made

publicly available so that anyone can study, modify,

distribute, make, and sell the design or hardware based on that

design. The hardware's source, the design from which it is made, is

available in the preferred format for making modifications to it.

Ideally, open source hardware uses readily-available components and

materials, standard processes, open infrastructure, unrestricted

content, and open-source design tools to maximize the ability of

individuals to make and use hardware. Open source hardware

gives people the freedom to control their technology while sharing

knowledge and encouraging commerce through the open exchange of

designs.

Essentially, if you release something as Open Source Hardware,

you're enabling other people to make their own versions of it, or

to improve it. There's more to it, though. Read on.

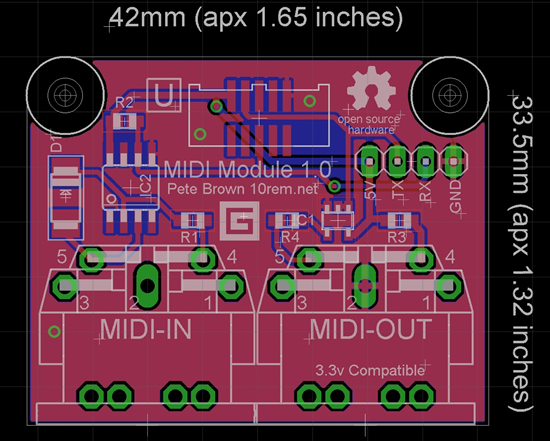

My most recent project is a simple MIDI interface for the .NET

Gadgeteer. I developed it in the open, with the advice of many

others on the forums. I've sent out for some prototype boards,

and once it looks like it'll work, I'll then publish the schematic

and board files officially. Developing it in the open allowed me to

get feedback and make the board better. It was also incredibly

motivating: I've had way too many projects just sit around and

collect dust because I got bored with them. That didn't happen

here; I credit the OSH approach and license for a big part of

that.

The version I sent out has vector fonts instead of

proportional fonts, slight board shrink down to 32mm high, and a

slight increase in clearance between the ground plane and traces,

but is otherwise the same. Notice the dimensions on the board: it's

pretty tiny. That SOT23-5 SMD logic chip is SMALL. Final schematics

coming when the board shows up (WIP stuff is linked to in that

thread)

Recently, my friend and fellow Microsoftie Andrew Duthie went

through a similar process (before I did) in designing his own .NET Gadgeteer

LED Array module. He also went through the very public process

of designing the prototype and folding in feedback

and working publicly on the API. His prototype doesn't have

the OSH logo on it anywhere, but it's OSH in process and (assuming

he releases the schematic and board design files) OSH in

result.

The product is much better for it, and everyone,

including the designer, benefits.

Free doesn't mean you can't make money

If you're working on a piece of hardware, consider

making it Open Source Hardware. This doesn't mean you

can't make money off of it. You can certainly manufacture the

hardware yourself, or sell kits, or whatever, and turn a profit

doing so. OSH and commercial work are not incompatible. Companies

like Secret Labs

and GHI

have entire branches dedicated to creating open source hardware and

software. They still manage to stay in business and actively create

cool stuff :)

Of course, many companies make money off the most popular of all

open source microcontroller platforms: the Arduino. In fact, I

can't think of any other OSH project which better exemplifies the

benefits of OSH. You can buy an official Arduino, build an Arduino

yourself either from a kit or on a breadboard, or you can use any

number of third-part versions of the Arduino, some with extra

features, some with smaller footprints or other enhancements. Other

people have taken the Arduino schematic and adapted it to create Arduino-compatible robot platforms.

Part of the reason companies can make money doing this is

because the barrier to entry for physical devices tends to be

higher than with code. Hardware design tools aren't as

collaboration-friendly as software tools in many cases. You'll have

some people who will take the design and go and manufacture

themselves, but you won't usually see as many contributions or

forks as you would with Open Source Software. Instead, you'll tend

to see more advice and contribution going back to the original

designer/manufacturer. Similarly, not everyone has the required

metal cutting tools to make the required parts for their own OSH

CNC machines or 3d Printers at home, and so they must rely on

others for those. A whole cottage industry has been built around

providing the harder to make parts for 3d printers like the Rep

Rap.

Want to see something cool? Head over to kickstarter

and enter "open source" for the search term. Open source

(particularly hardware) projects abound on this crowdfunding

site.

Why should you care?

By creating your work in the public and releasing as OSH, you

contribute to the community and to knowledge everywhere. You also

get back from the community ideas on how you could change the board

to make it better. Even better, you'll have people in the community

who take your design and augment to do things you probably never

even considered. Those designs must also remain OSH, so you benefit

from them as well.

Lots of great ideas simply die because the inventor didn't have

the means to manufacture them. Had they released it as OSH, it very

well would have been picked up (if a good idea) and made available.

Instead, they stay locked up in a vault on an off chance that the

inventor can figure out a way to manufacture them and maybe make a

few bucks in the future.

Now, you can definitely create Open Source Hardware without

using the logo and without associating yourself with OSH. However,

falling under a known framework will make it easier for everyone

else to understand exactly what your intentions are with regard to

rights.

Next time you make something, or start to make

something, be unambiguous and develop it in the open and with an

OSH license. It's fun. It's motivating. It's good for developers

and makers everywhere, and your product will almost certainly be

better for it.